If you’re offering Laser Cutting Services, it’s a highly precise and efficient method used to cut, engrave, and shape materials using a laser. Laser cutting is widely used across many industries, including manufacturing, automotive, aerospace, and sign-making, due to its ability to cut complex shapes with high precision and minimal material waste.

What is Laser Cutting?

Laser cutting involves the use of a high-powered laser to cut through materials such as metal, plastic, wood, glass, and more. The laser beam is focused onto the material, where it melts, burns, or vaporizes the material, creating a clean cut with minimal kerf (the material removed by the laser).

Types of Laser Cutting:

- CO2 Laser Cutting:

- Commonly used for cutting non-metal materials like wood, plastic, acrylic, and even some metals. CO2 lasers are versatile and highly accurate.

- Fiber Laser Cutting:

- Typically used for cutting metal materials, including steel, aluminum, brass, and copper. Fiber lasers are more energy-efficient and faster for metal cutting compared to CO2 lasers.

- YAG Laser Cutting (Yttrium Aluminum Garnet):

- This is a solid-state laser used in some specialized applications, typically for metalworking and precision cutting.

- Crystal Laser Cutting:

- A more advanced technology used for high-precision cuts on materials like ceramics, quartz, and hard metals.

Advantages of Laser Cutting:

- Precision: Laser cutting offers a high degree of precision with extremely tight tolerances, making it ideal for intricate designs.

- No Tool Wear: Unlike traditional cutting methods, there is no physical contact between the laser and the material, so there is no tool wear.

- Clean Cuts: Laser cutting produces smooth, clean edges with minimal burrs and no material deformation.

- Complex Shapes: Laser cutting allows for the creation of highly complex shapes and patterns that would be difficult or impossible to achieve with traditional methods.

- Minimal Material Waste: The precision of laser cutting ensures that minimal material is wasted during the process.

- Speed: Laser cutting can be faster than other cutting methods, especially for high-volume production.

- Automation: Laser cutting can be easily automated for large-scale production, making it efficient and consistent.

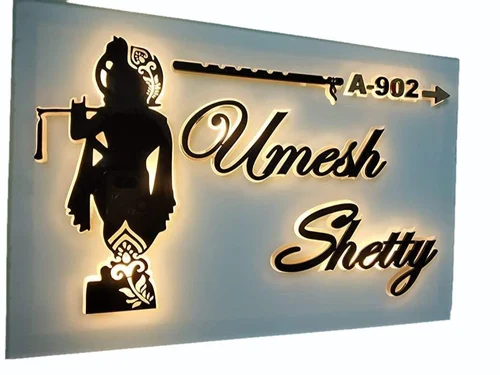

Acrylic Sheet Laser Cutting Service

In order to cater the variegated demands of our precious clients, we are offering an excellent quality range of Acrylic Sheet Laser Cutting Service